color case hardening temperature

Color Case Hardening Temperatures. Dont go over 1350 F.

Evenheat Kiln Inc Ht 1 Heat Treat Oven And Color Case Hardening Kit Brownells

Color Case Hardening Services.

. We keep our temperatures below hardening temperatures. You have to watch the temperature more closely with color case. Kasenit and similar compounds are a lot.

Working temperature ranges from 1200 to 1600 degrees f. You have to watch the temperature more closely with color case hardening or the colors wont come out well. To achieve these results we use the traditional method of packing the.

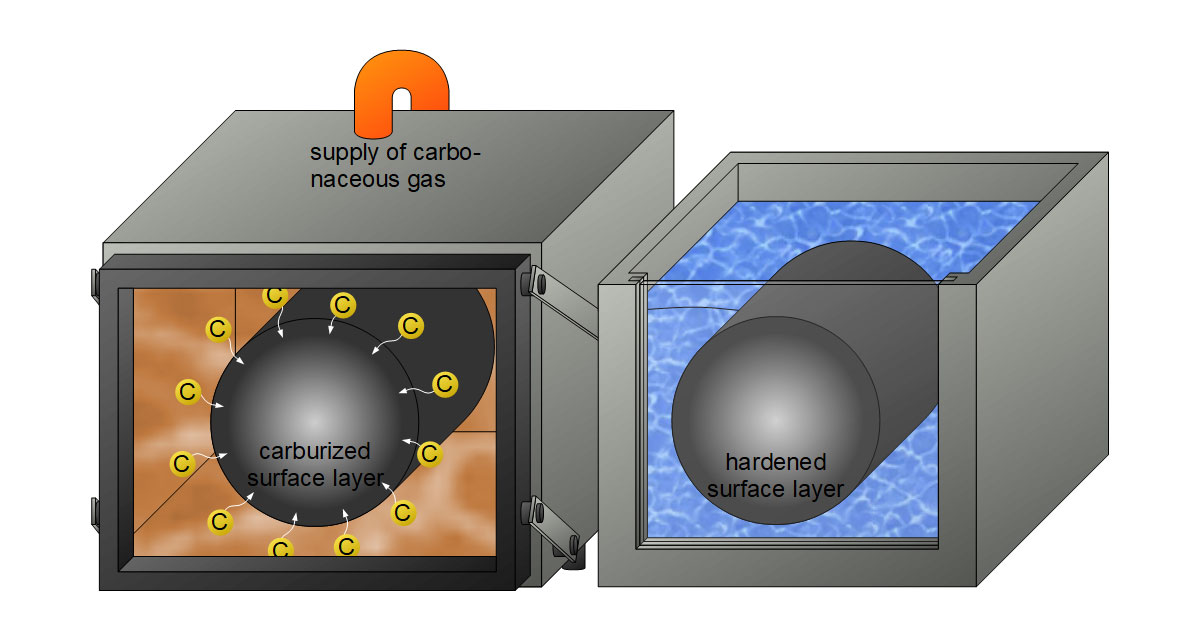

Then the steel will be held at a relatively high temperature between 850c to 950 c for a prescribed period. This is why the process is also referred to as surface hardening or single quench hardening from surface hardening temperature. Senior Forum Member Offline Posts.

Color Case Hardening Temperatures Read 7000 times sakoman. Contact Brownells and ask for their instructions for color case hardening. In principle the hardening temperature can.

Canoe Creek Case Hardening. Starting with yellow then blue and purple in a continuous transition. A lot of really old model rifles have color case hardening these days but i love to see handguns that have this.

Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. From the earliest guns that were. Recommendations to highly polish all parts and recommendations to not ex - ceed 240 grit.

Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade. Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. It is heated to somewhere around 1200 to 1400 degrees.

Wyoming Armory is a custom gunsmithing shop where we build custom firearms but one of our specialities is tradional bone charcoal color case hardening. Temperatures from 1250 to 1500 F and heating times of from 1 to 5 hours. Our color case is done using a mixture of bone and wood charcoal.

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. It is heated to somewhere around 1200 to 1400 degrees and then quenched. Feb 20 th 2006.

These colors were developed during tempering heat-treatment after case hardening. The hot steel will then be quenched quickly in a cold liquid such as water or oil the.

What Is Case Hardening And How To Make It Look Great Wayken

Stainless Steel Patina Stainless F X

American Handgunner When You Re Hot American Handgunner

Home Oven Steel Tempering Coloring 4 Steps With Pictures Instructables

Wyoming Armory Precision Firearms Color Case Hardening Specialists Color Case Hardening Services

Wyoming Armory Precision Firearms Color Case Hardening Specialists Color Case Hardening Services

What Is Case Hardening And How To Make It Look Great Wayken

Case Hardening Surface Hardening Tec Science

Do It Yourself Color Case Hardening Patinas Procedures For Guns Gun Parts Knife Blades Youtube

Color Case Hardening Turnbull Restoration

Interpreting Carburized Case Depths 2014 07 08 Industrial Heating

Wyoming Armory Precision Firearms Color Case Hardening Specialists Color Case Hardening Services

Color Case Hardening And Heat Treating Upland Gun Company

Color Case Hardening The Exhaustnotes Blog

Color Case Hardening Effect Using Cold Blue Youtube

The History Of Case Hardening And Its Processes Double Stone Steel

Tempering Temperature An Overview Sciencedirect Topics